MBR

Membrane Bioreactors (MBRs) stand at the forefront of advanced wastewater treatment, integrating biological processes with membrane filtration technology. MBR applications extend to various sectors, including municipal wastewater treatment, industrial effluent purification, and water reuse projects. The improved effluent quality, higher biological efficiency resulting in a 30-40% reduced footprint, and the ability to handle variable flow rates make MBRs well-adapted to diverse wastewater treatment scenarios.

Among cutting-edge solutions, our BIO-CEL stands out with its patented self-healing laminate technology—a proven innovation spanning over 15 years. This technology seamlessly integrates the advantages of both flat sheet and hollow fiber membranes, creating a robust and efficient MBR solution. The self-healing membrane technology embedded in BIO-CEL addresses critical challenges with the durability of membranes faced by traditional MBR applications. This innovation ensures reliable filtration quality, fouling resistance, and significantly reduces the need for frequent and disruptive cleaning, thus minimizing downtime, in addition to its 360-degree accessible module design.

Within the MBR framework, the choice of membrane materials becomes pivotal, with Polyethersulfone (PES) and Polyvinylidene Fluoride (PVDF) standing out for their unique characteristics. MANN+HUMMEL's PES-based UP150 membrane has firmly established its presence in the MBR market since the inception of the BIO-CEL L Series. In response to the evolving needs of MBR applications, we have developed the UV400 membrane. The UV400 membrane brings advanced features and performance enhancements within the BIO-CEL L+ Series.

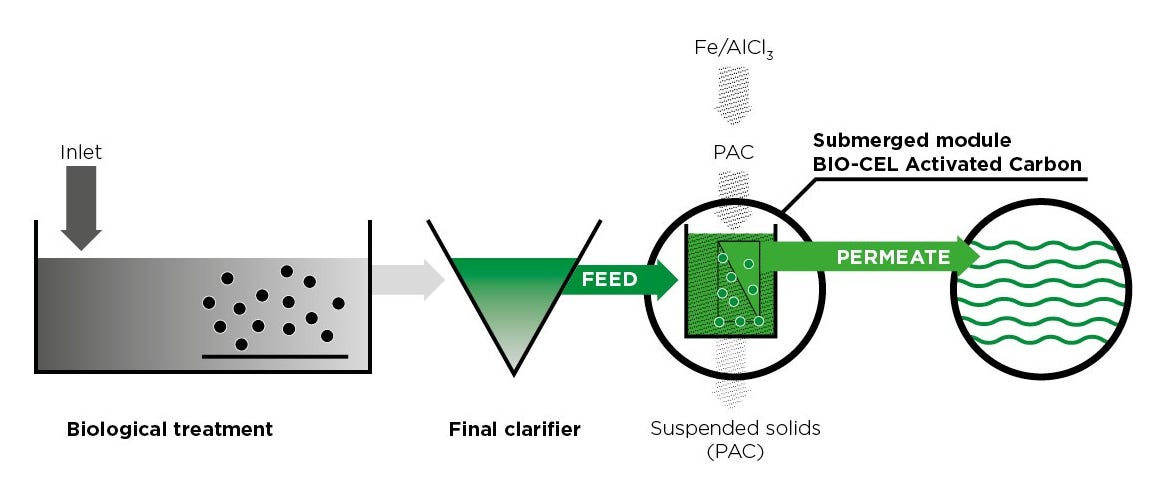

Whether using our UP150 membrane in the L Series or UV400 membrane in our new L+ Series, BIO-CEL continues to be at the forefront of MBR innovation, offering a comprehensive range of solutions to meet the diverse needs of wastewater treatment and beyond. As an innovation leader, MANN+HUMMEL developed a patented application where antibiotic-resistant bacteria and genes, microplastics, and micropollutants are removed within one process comprising membrane filtration paired with powdered activated carbon.

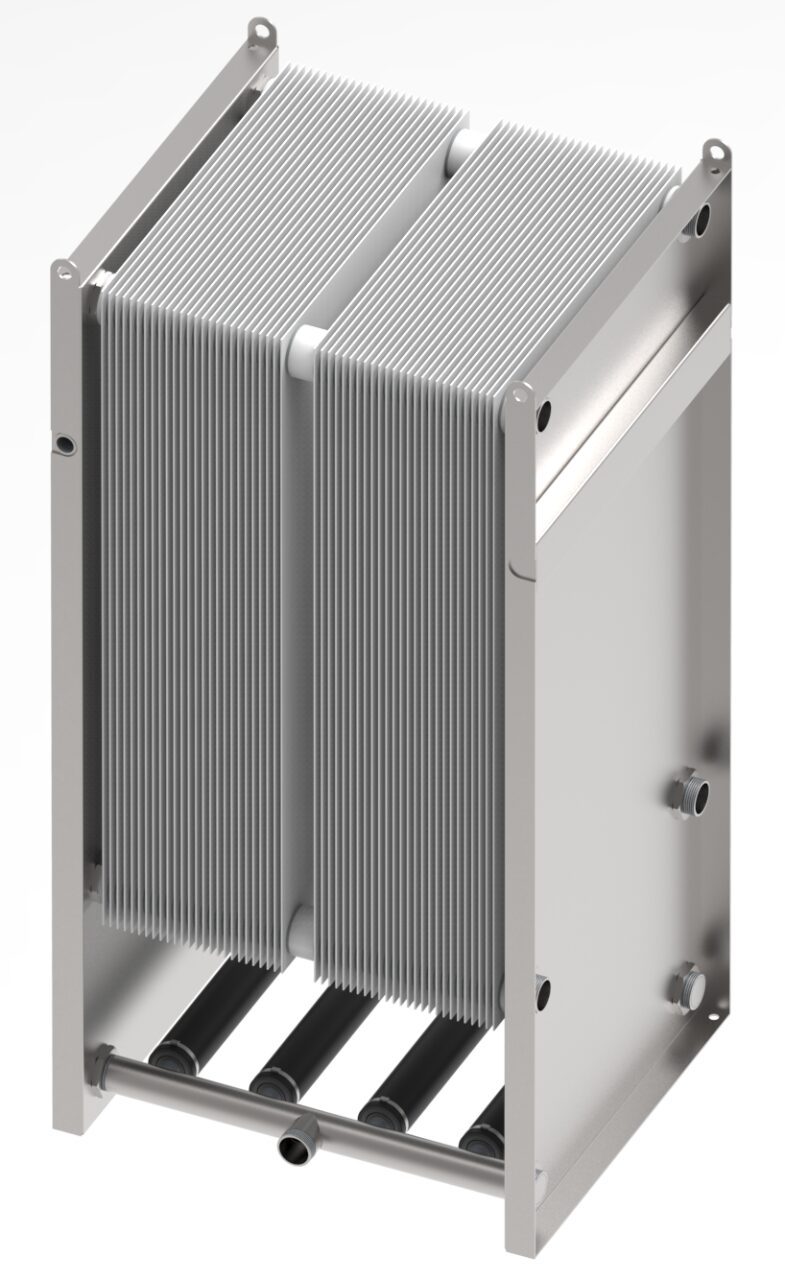

Our BIO-CEL product lines

Take a closer look into our membrane bioreactors (MBR) - the leading innovation in wastewater treatment.

In order to meet the evolving needs of our Customers and continuously improve our products, we always keep updating our BIO-CEL product line. The new range is leaner and extendable, offering higher packing density and increased efficiency.

Advantages

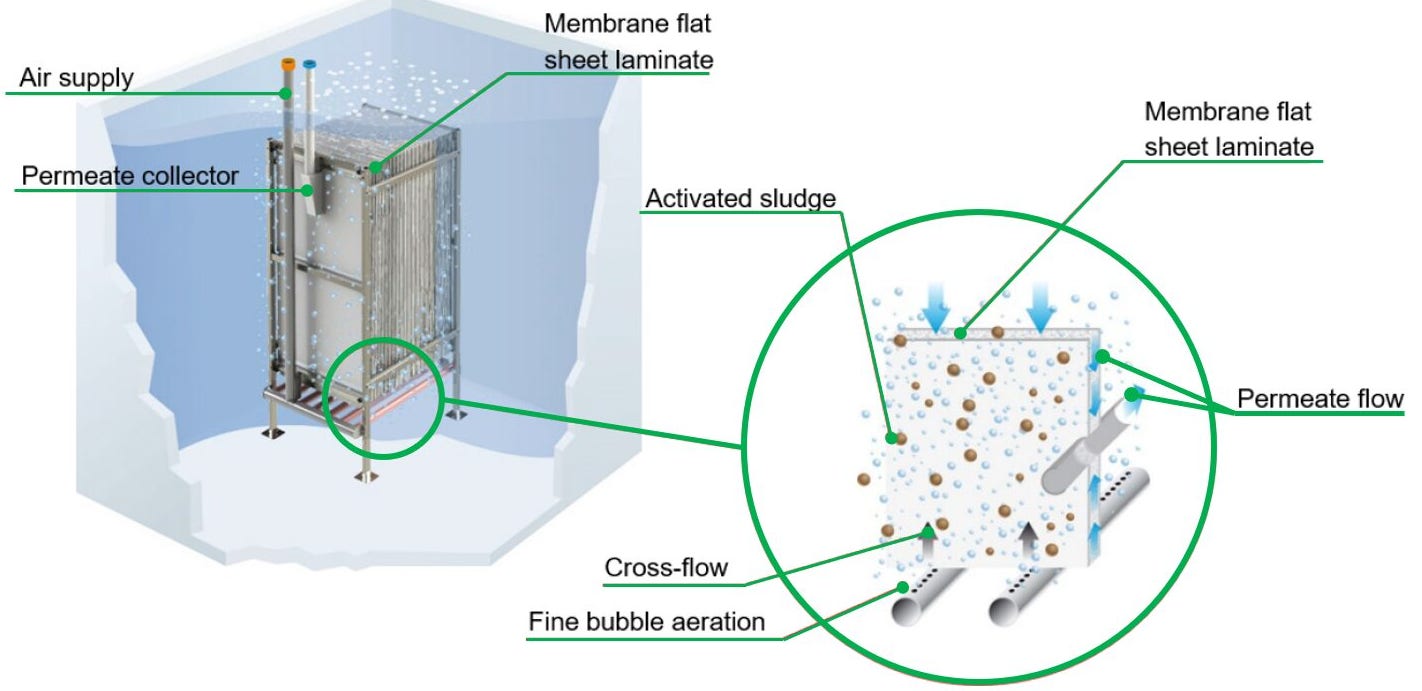

- high effluent quality (effective retention of solids and bacteria)

- smart module design (less braiding and sludge depositions)

- backflushable module based on flat sheet membranes

- small footprint (high packing density)

- reduced energy demand

- unique membrane laminate with self healing effect

- optimized oxygen transfer (fine bubble aeration)

How it works

Activated Carbon Method

Check how the membrane filtration paired with powdered activated carbon works.