Dairy Process

At MANN+HUMMEL, we understand that the dairy industry requires innovative technologies to meet the demands of such a rapidly evolving market. With our expertise in membrane technology, we are dedicated to providing top-tier solutions that enhance dairy processing safety, efficiency, quality, and sustainability.

Our comprehensive range of membranes is specifically designed to optimize various stages of dairy production. From milk processing and protein fractionation to whey concentration and lactose production, our customizable membrane solutions cater to diverse industry needs, ensuring higher yields, improved product quality, and cost-effective operations.

Main Applications

- Protein Concentration

- Selective Product Concentration

- Fat Removal

Protein Concentration

Whey, a biproduct of cheese or casein production, is concentrated using ultrafiltration membranes to produce whey protein concentrate (WPC) or whey protein isolate (WPI).

Selective Product Concentration

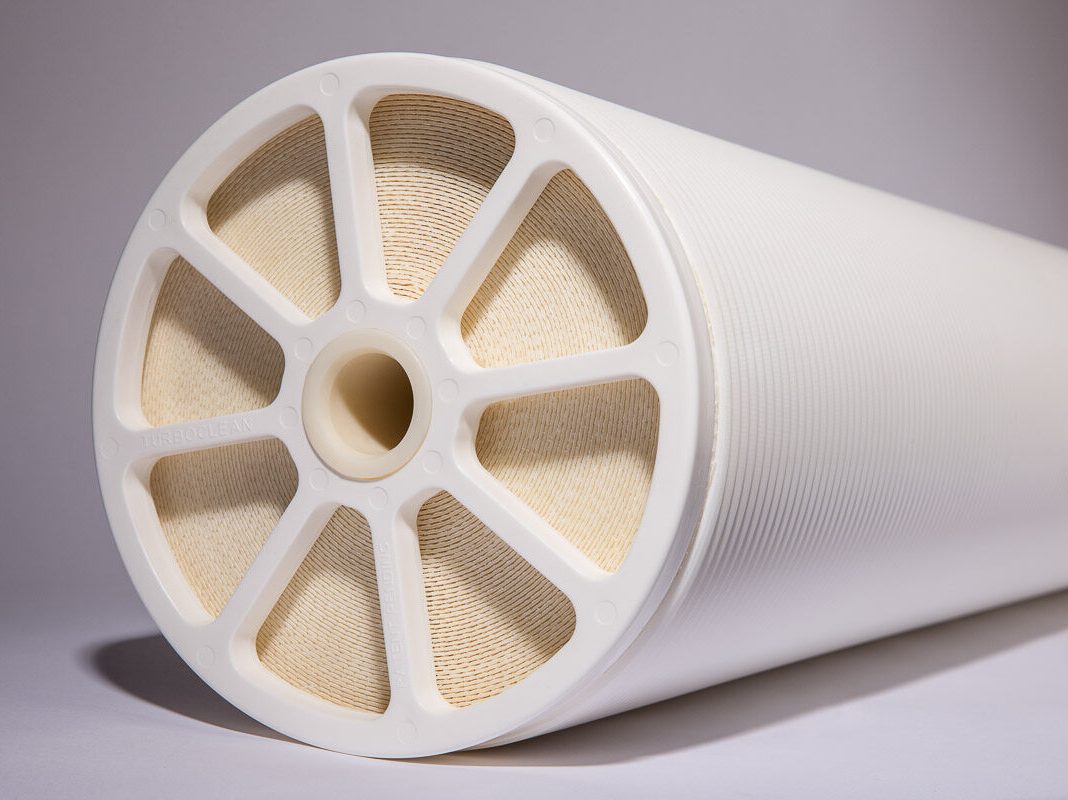

Concentrating and demineralizing milk, whey and lactose allows dairies to tailor the milk, whey and lactose properties to meet specific production and product requirements ensuring consistent quality. MANN+HUMMEL’s TRISEP DS and TurboClean line of NF and RO sanitary products provide excellent performance characteristics built to the highest quality standards to ensure final product quality.

Fat Removal

Whey defatting, via microfiltration, is often employed to enhance the overall nutritional profile of whey protein concentrates and isolates. MANN+HUMMEL’s TRISEP DS and TurboClean MF sanitary products are specially designed to provide a reliable, long-lasting performance.